Different Types of 3D Printing !

3D printing is that the latest thing to excite anyone who loves easy-to-use interactive technology. Engineers and scientists have actually been working with this amazing equipment since way back in 1983. That’s the time when an American engineer named Charles (Chuck) Hull invented the primary ever 3D printer. He called it his SLA machine, which stands for stereolithography apparatus. Some within the industry seek advice from a part of the 3D printing as Additive Manufacturing (AM), but we’ll use its practical name here—3D Printing. this can keep the guide consistent and straightforward to read.

The Reasons for Several forms of 3D Printer.

The reasons there are differing kinds of 3D printers and printing processes are just like that of the 2D printers we’re so conversant in.It all comes all the way down to the subsequent six considerations:

- Printer cost

- Print quality

- Print speed

- Printer capability

- Practicality

- User expectations

Some printers only print text—others text and graphics. The technologies and materials used also vary, and also the way the machine extrudes ink to paper. 3D printers are even smarter. And like their 2D counterparts, they also offer a variety of options including quality, materials, and price.

The 3D printing in a very Nutshell.

The 3D printing isn't any longer difficult for the house user once you grasp the essential principles. OK, so printers, printing materials, printed objects, and 3D printing software can all vary. Yet despite this, the method from design to finish product follows an identical path. And here’s how it's in a very nutshell:

User has access to a 3D modeling application or a 3D scanner.

User creates a virtual design (3D model) of the article they need to print in 3D.

User typically saves their design as a Computer Aided Design file, or CAD for brief

User slices their CAD file before sending it to the printer.

User uploads spliced 3d Models into the printer.

Printer reads each slice within the 2D file to form the three dimensional object.

Who is that this Guide For?

This simple guide is for those that want to know the differences between different 3D printing types. It’s also for hobbyists, schools, libraries, and anyone else who wants to speculate during this amazing technology.

If you recognize nothing in the least about 3D printing—but would really like to learn—this guide is for YOU. Don’t worry, we’re not visiting overwhelm you or blind you with science. By the top of this guide, you’ll have a decent, basic understanding of all the 3D printer types available today. If you’re considering investing in a very 3D printer, we’ve got you covered. You’re visiting be in a very far better position to create a well-informed decision before parting together with your hard-earned cash.

The Focus of this Guide

This guide focuses on the foremost common forms of 3D printers in use today. We’ll introduce each of those machines by their long names first. at the moment we’ll use the acceptable acronyms to stay the reading easy. for instance, stereolithography becomes SLA. And Laminated Object Manufacturing becomes LOM, as two examples.

Here are the Different 3D printer types you'll learn about:

Stereolithography (SLA)

Digital Light Processing (DLP)

Fused deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Selective Laser Melting (SLM)

Electronic Beam Melting (EBM)

Laminated Object Manufacturing (LOM)

Binder Jetting (BJ) Material Jetting (MJ)

The Basic Components of a 3D Printer.

Before we start to seem at the varied 3D printer types and printing practices, we’ll take a flash to list the most components of those machines. There are many parts, and every one plays a vital role within the printing. We’re not visiting get too technical here. It’s still important, however, to grasp what the most components are. this may facilitate your to raised understand the printing processes as you read through the varied sections.

The main components, and their use, during a 3D printer are:

- 3D Printer Frame: Holds the machine together.

- 3D Printer Head movement mechanics: moves relative to the print bed altogether directions.

- 3D Printer Head: Nozzle that deposits filament or applies colors and liquid binder.

- 3D Build Platform or Build Bed: The a part of the printer where the item is printed.

- 3D Printer Stepper Motors (at least 4): Used for precise positioning and speed control.

- 3D Printer Electronics: accustomed drive motors, heat the extruder and far more.

- 3D Printer Firmware: Permanent software accustomed control every aspect of a 3D printer.

- 3D Printer Software: Not a part of the particular printer but still needed for the printing.

3D Support Substances

Many 3D printers use various substances that support complex geometries. Support materials are as essential to the 3D printing because the actual base materials. Without support during the build there wouldn't be a successful outcome. These materials offer a far better solution than the old physical support structures of the past. Once printing is complete, the user simply removes any support substance from the finished part.

Some 3D technologies use support materials that dissolve when placed into a chemical bath. Others will use the encircling powder as some way to stay everything in situ. And there are those which use a squidgy, gel-like substance.

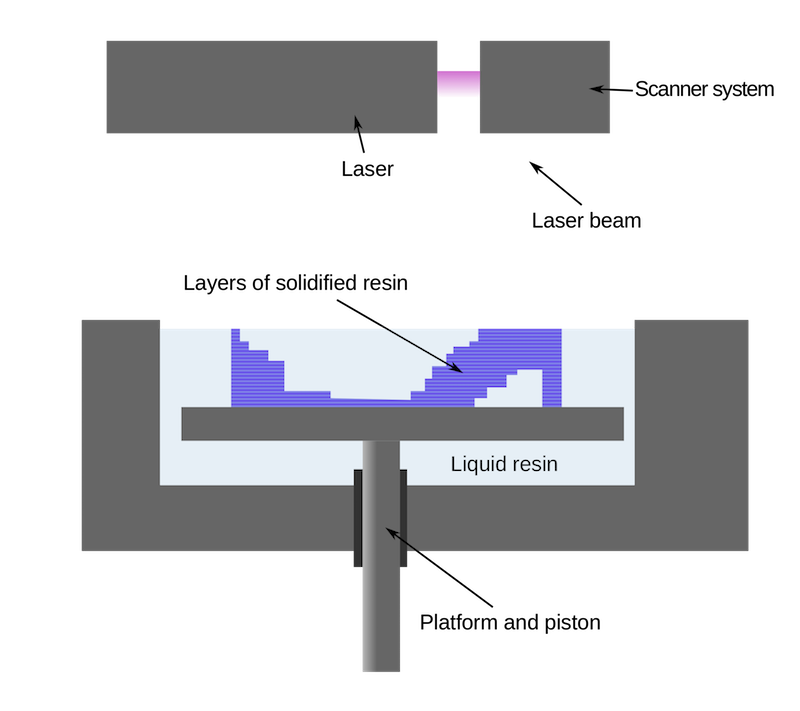

1) Stereolithography (SLA) Printer.

SLA could be a fast prototyping process. people who use this technology are serious about accuracy and precision. It can produce objects from 3D CAD data (computer-generated) files in mere some hours. this is often a 3D writing that’s popular for its fine details and exactness. Machines that use this technology produce unique models, patterns, prototypes, and various production parts. they are doing this by converting liquid photopolymers (a special form of plastic) into solid 3D objects, one layer at a time. The plastic is first heated to show it into a semi-liquid form, then it hardens on contact. The printer constructs each of those layers using an ultra violet laser, directed by X and Y scanning mirrors. Just before each print cycle, a recoater blade moves across the surface to confirm each thin layer of resin spreads evenly across the thing. The print cycle continues during this way, building 3D objects from the underside up.

Once completed, someone takes the 3D object from the printer and detaches it carefully from the platform. The 3D part will usually have a chemical bath to get rid of any excess resin. It’s also common practice to post-cure the thing in an ultra violet oven. What this does is render the finished item stronger and more stable. looking on the part, it's going to then bear a hand sanding process and have some professional painting done. SLA printing has become a popular economical choice for a good sort of industries. a number of these include automotive, medical, aerospace, entertainment, and also to form various consumer products.Some SLA printers include are 3D printer Pegasus Touch SLA technology, XYZprinting Nobel 1.0 SLA 3D Printer, SUNLU SLA Desktop 3D Printer, Form 1+ SLA 3D Printer.

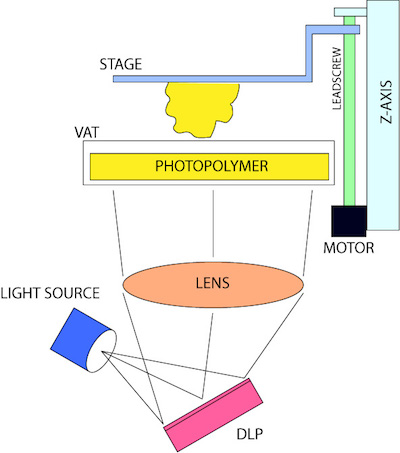

2) Digital Light Processing (DLP) Printer.

DLP is that the oldest of the 3D printing technologies, created by a person called Larry Hornbeck back in 1987. It’s kind of like SLA (see above), on condition that it also works with photopolymers. The liquid plastic resin utilized by the printer goes into a translucent resin container. There is, however, one major difference between the 2, which is that the source of sunshine. While SLA uses ultra violet light, DLP uses a more traditional source of illumination, usually arc lamps. This process leads to pretty impressive printing speeds. When there’s lots of light, the resin is quick to harden (we’re talking seconds). Compared to SLA 3D printing, DLP achieves quicker print times for many parts. the explanation it’s faster is because it exposes entire layers directly. With SLA printing, a laser needs to put off each of those layers, and this takes time.

Another plus point for DLP printing technology is that it's robust and produces high resolution models when. It’s also economical with the power to use cheaper materials for even complex and detailed objects. this is often something that not only reduces waste, but also keeps printing costs low.Some DLP printers include are Makex M-one Desktop DLP 3d Printer, Desktop UV DLP, LumiPocket – Miniature DLP, Solus DLP 3D Printer

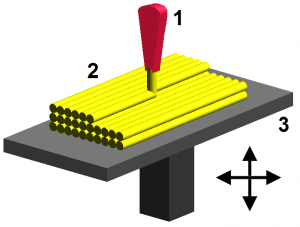

3) Fused Deposition Modeling (FDM) Printer.

FDM could be a 3D writing developed by Scott Crump, then implemented by Stratasys Ltd., within the 1980s. It uses production grade thermal plastic materials to print its 3D objects. It’s popular for producing functional prototypes, concept models, and manufacturing aids. It’s a technology which will create accurate details and boasts an exceptional strength to weight ratio.

Before the FDM writing begins, the user needs to slice the 3D CAD data (the 3D model) into multiple layers using special software. The sliced CAD data goes to the printer which then builds the thing layer at a time on the build platform. It does this just by heating then extruding the thermoplastic filament through the nozzle and onto the bottom. The printer may also extrude various support materials similarly because the thermoplastic. for instance, as the way to support upper layers, the printer can add special support material underneath, which then dissolves after the writing. like all 3D printers, the time it takes to print all depends on the objects size and its complexity.

Like many other 3D technologies, the finished object needs cleaning. Raw FDM parts can show fairly visible layer-lines on some objects. These will obviously need hand sanding and finishing after printing. this is often the sole thanks to get a smooth, end result with an excellent surface. FDM finished objects are both functional and sturdy. This makes it a well-liked process to be used in an exceedingly wide selection of industries, including for engineering science and parts manufacturers. BMW uses FDM 3D printing, as does the well-known company Nestle, to call just a pair.Some FDM printers include are JGAURORA 3d Desktop FDM Printer, ALUNAR High Resolution Desktop FDM 3D Printer, Original Prusa i3 MK2, PowerSpec 3D Pro, Lulzbot Mini, FlashForge Creator Pro.

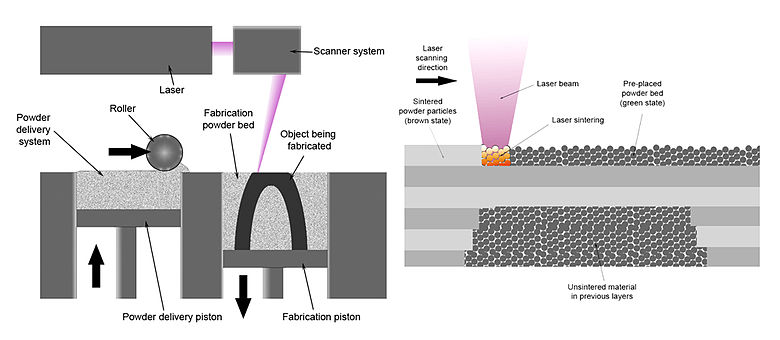

4) Selective Laser Sintering (SLS) Printer.

An American businessman, inventor, and teacher named Dr. Carl Deckard developed and patented SLS technology within the mid-1980s. It’s a 3D printing technique that uses high power CO2 lasers to fuse particles together. The laser sinters powdered metal materials (though it can utilize other materials too, like white nylon powder, ceramics and even glass). Here’s how it works:

The build platform, or bed, lowers incrementally with each successive laser scan. It’s a process that repeats one layer at a time until it reaches the object’s height. there's un-sintered support from other powders during the build process that surround and protect the model. this implies the 3D objects don’t need other support structures during the build. Someone will remove the un-sintered powders manually after printing. SLS produces durable, high precision parts, and it can use a good range of materials. It’s an ideal technology for fully-functional, end-use parts and prototypes. SLS is kind of the same as SLA technology with regards to hurry and quality. the most difference is with the materials, as SLS uses powdered substances, whereas SLA uses liquid resins. It’s this wide selection of obtainable materials that produces SLA technology so popular for printing customized objects.Some SLA printers include are XYZprinting Nobel 1.0 SLA 3D Printer, SUNLU SLA Desktop 3D Printer, Formlabs Form 2, 3D Systems ProJet 1200, DWS Lab Xfab.

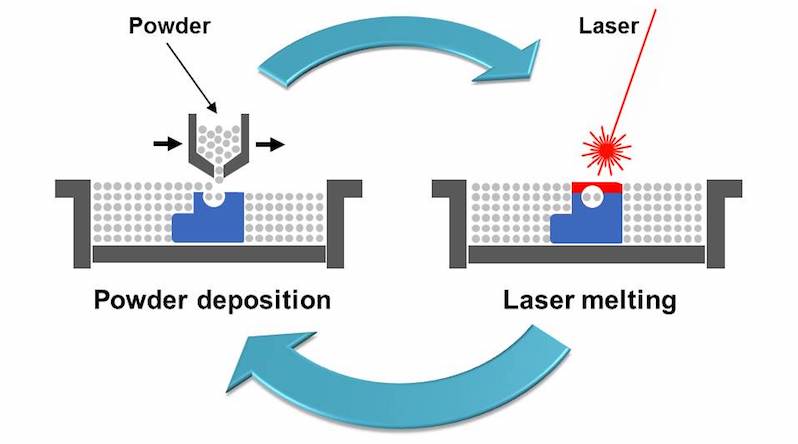

5) Selective Laser Melting (SLM) Printer.

SLM made its debut appearance back in 1995. it absolutely was a part of a German research at the Fraunhofer Institute ILT, located within the country’s most western city of Aachen. Like SLA (see above), SLM also uses a high-powered light beam to create 3D parts. During the writing, the light beam melts and fuses various metallic powders together. the easy thanks to study this is often to interrupt down the fundamental process like thus:

Powdered material + heat + precision + layered structure = an ideal 3D object.

As the light beam hits a skinny layer of the fabric, it selectively joins or welds the particles together. After one complete print cycle, the printer adds a brand new layer of powered material to the previous one. the thing then lowers by the precise amount of the thickness of one layer. When the print process is complete, someone will manually remove the unused powder from the thing. the most difference between SLM and SLS is that SLM completely melts the powder, whereas SLS only partly melts it (sinters). In general, SLM end products tend to be stronger as they need fewer or no voids.

A common use for SLM printing is with 3D parts that have complex structures, geometries and thin walls. The aerospace industry uses SLM 3D printing in a number of its pioneering projects. These are typically those which specialize in precise, durable, lightweight parts. It’s a costly technology, though, and then not practical or popular home users for that reason. SLM is kind of widespread now among the aerospace and medical orthopedics industries. those that invest in SLM 3D printers include researchers, universities, and metal powder developers. There are others too, who are keen to explore the total range and future potential of metal additive manufacturing specifically.Some SLM industrial printers include are SLM Solutions SLM 125, 280, and 500, Realizer SLM 125, Optomec LENS 450, others.

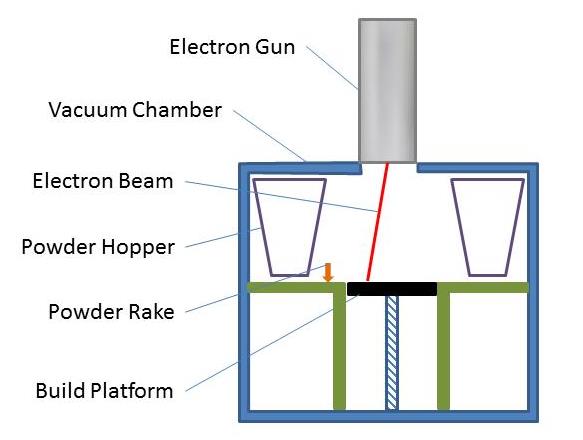

6) Electromagnetic radiation Melting (EBM) Printer.

A Swedish company called Arcam AB founded EBM® in 1997. this is often a 3D printing technology the same as SLM (see above), in this it uses a powder bed fusion technique. The difference between the 2 is that the power source. The SLM approach above uses high-powered laser in a very chamber of noble, or noble gas. EBM, on the opposite hand, uses a robust electromagnetic radiation in a very vacuum. other than the ability source, the remaining processes between the 2 are quite similar. EBM’s main use is to 3D print metal parts. Its main characteristics are its ability to attain complex geometries with freedom of design. EBM also produces parts that are incredibly strong and dense in their makeup.

Here are some of EBM’s other impressive features:

- Doesn’t need extra electronic equipment for the 3D writing

- Has increased efficiency using raw materials

- Lessens lead times leading to parts aiming to market faster

- Can create fully functional, durable parts on demand for wide-ranging industries

- The writing starts like most others in this the user should first create a 3D model, or computer-generated digital file. An industrial EBM printer includes are Arcam Q20

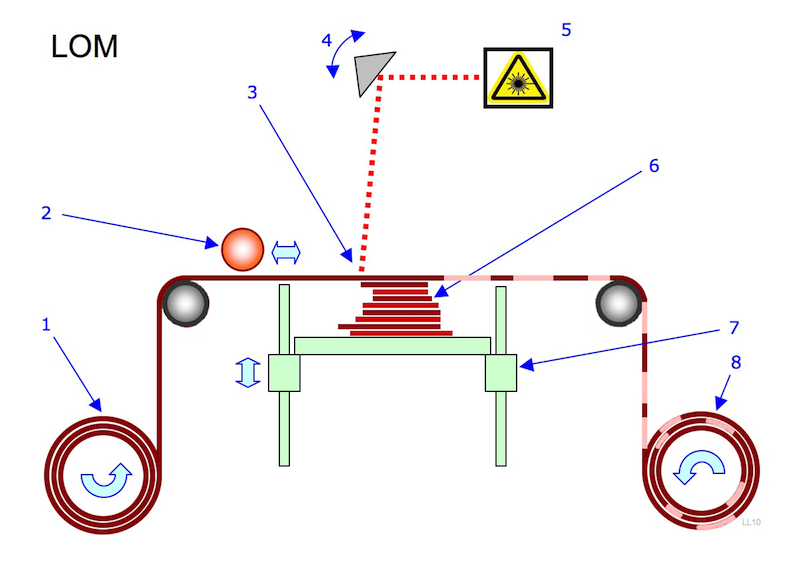

7) Laminated Object Manufacturing (LOM) Printer.

A Californian company called Helisys Inc. (now Cubic Technologies), first developed LOM as an efficient and affordable method of 3D printing. A US design engineer called Michael Feygin—a pioneer in 3D printed technologies—originally patented LOM.

LOM could be a rapid prototyping system that works by fusing or laminating layers of plastic or paper using both heat and pressure. A computer-controlled blade or laser cuts the thing to the specified shape. Once each printed layer is complete, the platform moves down by about 1/16th of an in., ready for the subsequent layer. The printer then pulls a brand new sheet of fabric across the substrate where it’s adhered by a heated roller. This basic process continues over and over until the 3D part is complete.

According to Wikipedia, the LOM printing works as follows:

- Sheet is adhered to a substrate with a heated roller.

- Laser traces desired dimensions of prototype.

- Laser cross hatches non-part area to facilitate waste removal.

- Platform with completed layer moves down out of the way.

- Fresh sheet of fabric is rolled into position.

- Platform downs into new position to receive next layer.

- The process is repeated.

- It might not be the foremost popular method of 3D printing today, but LOM remains one in every of the fastest nonetheless. It’s also perhaps the foremost affordable method for creating 3D prototypes. the rationale for this is often thanks to the low cost of materials used (papers and plastics). It’s also a process which will create fairly large 3D printed objects. those that still use LOM printers today include architects, artists, and merchandise developers.One popular LOM printer is The Mcor Matrix

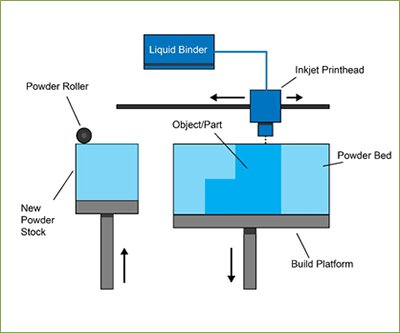

8) Binder Jetting (BJ) Printers.

The Massachusetts Institute of Technology (MIT) first invented BJ 3D printing. you'll also hear this technology said in other names, including:

- Powder bed printing

- Inkjet 3D printing

- Drop-on-powder

- Binder jetting (BJ). this is often the foremost popular name and therefore the one we’ll use to talk to it.

- BJ could be a 3D writing that uses two kinds of materials to make objects: a powder-based material (usually gypsum) and a bonding agent. because the name suggests, the “bonding” agent acts as a robust adhesive to connect (bond) the powder layers together. The printer nozzles extrude the binder in liquid form the same as a daily 2D inkjet printer. After completing each layer, the build plate lowers slightly to permit for the subsequent one. This process repeats until the thing reaches its required height.

The four popular materials utilized in BJ printing include:

- Ceramics

- Metals

- Sand

- Plastics

It’s unimaginable to urge super high-resolution or overly rugged 3D objects with BJ printing, but there are other advantages. for instance, these printers allow you to print parts fully color. To do this, you just add color pigments to the binder, which usually include black, white, cyan, yellow, and magenta. This technology remains advancing, so expect more great things to return within the future. At the time of writing, some applications of BJ 3D printing include rapid prototyping, and various uses within the aerospace, automotive, and medical industries.Some BJ printers include are Addwii Unveils The X1, ExOne R2, ZCorp Spectrum z510

9) Material Jetting (MJ) Polyjet and Wax Casting Printer.

You will also hear Material Jetting said as wax casting. Unlike other 3D printing technologies, there isn’t one inventor for MJ. In fact, up until recent times it’s been more of a way than an actual writing. It’s something jewelers have used for hundreds of years. Wax casting has been a conventional process where the user produces high-quality, customizable jewelry. the rationale it gets a mention here is thanks to the introduction of 3D printing. due to the arrival of this technology, wax casting is now an automatic process. Today, MJ 3D printers produce high-resolution parts, mainly for the dental and jewellery industries,

For jewelers who want to experiment with various casts—as most jewelers do—MJ is now their leading 3D technology. At the time of writing, there are some high-quality professional wax 3D printers on the market. Here’s how they work:

Once the 3D model (CAD file) is uploaded to the printer, it’s all systems go. The printer adds molten (heated) wax to the aluminum build platform in controlled layers. It achieves this using nozzles that sweep evenly across the build area. As soon because the heated material lands on the build plate it begins to chill down and solidify (UV light helps to cure the layers). because the 3D part builds up, a gel-like material helps to support the writing of more complex geometries. Like all support materials in 3D printing, it’s easy to get rid of it afterward, either by hand or by using powerful water jets. Once the part is complete you'll use it instantly, no further post-curing necessary.

There also are Polyjet MJ 3D printers, which use photopolymer-resins instead of synthetic waxes. Polyjet technology also offers superb resolution. Unlike digital wax printers, people use Polyjet devices to make parts for a good range of industries.Some MJ printers include are ABS 3D printer, PLA 3D printer (large format), HP Multi Jet Fusion.

Summary :

3D printers and print technology is advancing all the time. As it does, prices will still fall because the devices and processes become ever more impressive. If you’ve read this guide from top to bottom, you'll now have an honest basic understanding of the various 3D printers and the way they work. you'll also know of the varied materials printers use and also the industries they support. And if you wish a refresher, you'll simply revisit any section of this guide at any time.

No comments